Rokonma is Malaysia’s leading manufacturer of conveyor rollers and accessories. Our products are trusted in both bulk handling and unit handling industries, combining competitive pricing with uncompromising quality. Guided by our vision, we aim to be the foremost supplier of conveyor idlers and accessory parts across Malaysia.

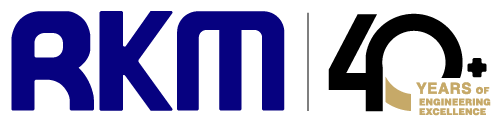

RS Steel Roller

RKM-RS steel roller are suited for the harshest mining conditions. With its optimum sealing package and quality components, RKM-RS rollers is one of our best seller and supplied to various projects around the world.

Specification

- Tube: Electric Resistance Welding (ERW) 200-350 steel tube. BS1387:1995, GB/T13793:2008 or other equivalent standard.

- Shaft: Mild steel cold drawn bars. JIS G3123, GB/T 3078-2008 or other equivalent standards Bearing Housing: SPHC orSPCC. JIS G3131 or other equivalent standards.

- Bearings: ZZ C3 Deep groove ball bearings.

- Seals: Labyrinth seals, rear seals and outer protective shields made from high grade nylon. NBR lip seal for added protection against water and slurry.

- Welding: 3mm continuous fillet weld.

- Corrosion protection: Anti rust oil, color alkyd paint or powder coating.

Features

- Roller operating temperature -20ºC to 100ºC.

- Rollers are tested in our labs according to DIN22112-3 standard.

- Typical applications are overland conveyors, ports, cement plants and coal fired power plants.

- We are able to cater various roller standards such as JIS B 8803, DIN 22112-2, CEMA and Australian standards.

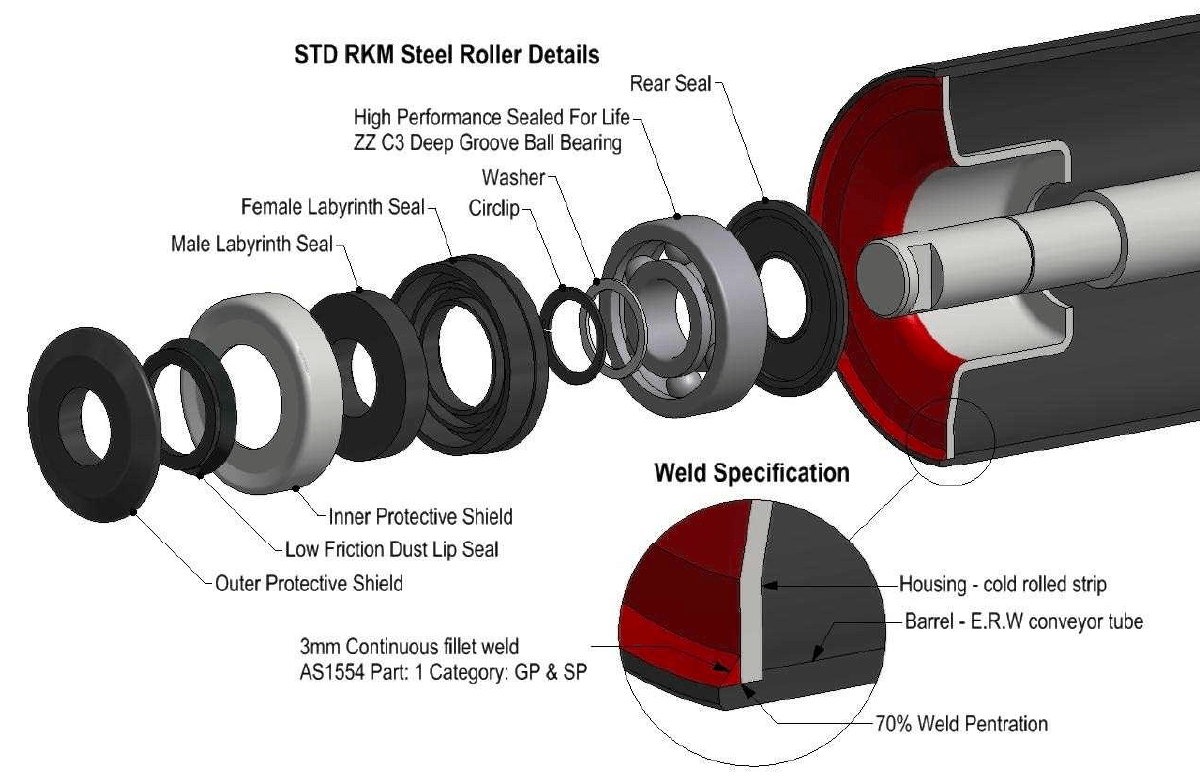

Low Noise & Weigh Rollers

Low Noise rollers can be applied on heavy duty mining conditions close to residential area where minimal noise emission level is allowed.

Weigh rollers are used in weighing section of the conveyor belt where minimal unbalanced weight is permitted

Features

- Low noise rollers are dynamically balance to ISO1940 – G16 grade.

- Weigh rollers are dynamically balance to ISO1940-G16 or 0.014Nm, whichever is more stringent.

- Roller surface machined to achieve the highest eccentricity or Total Run-out Indicator(TIR) and Mean Indicator Slope (MIS)

- Noise level reduction of more than 10dBA as compared to normal steel rollers.

- Low noise and weigh rollers requires double the amount of fabrication process as compared to normal steel rollers.

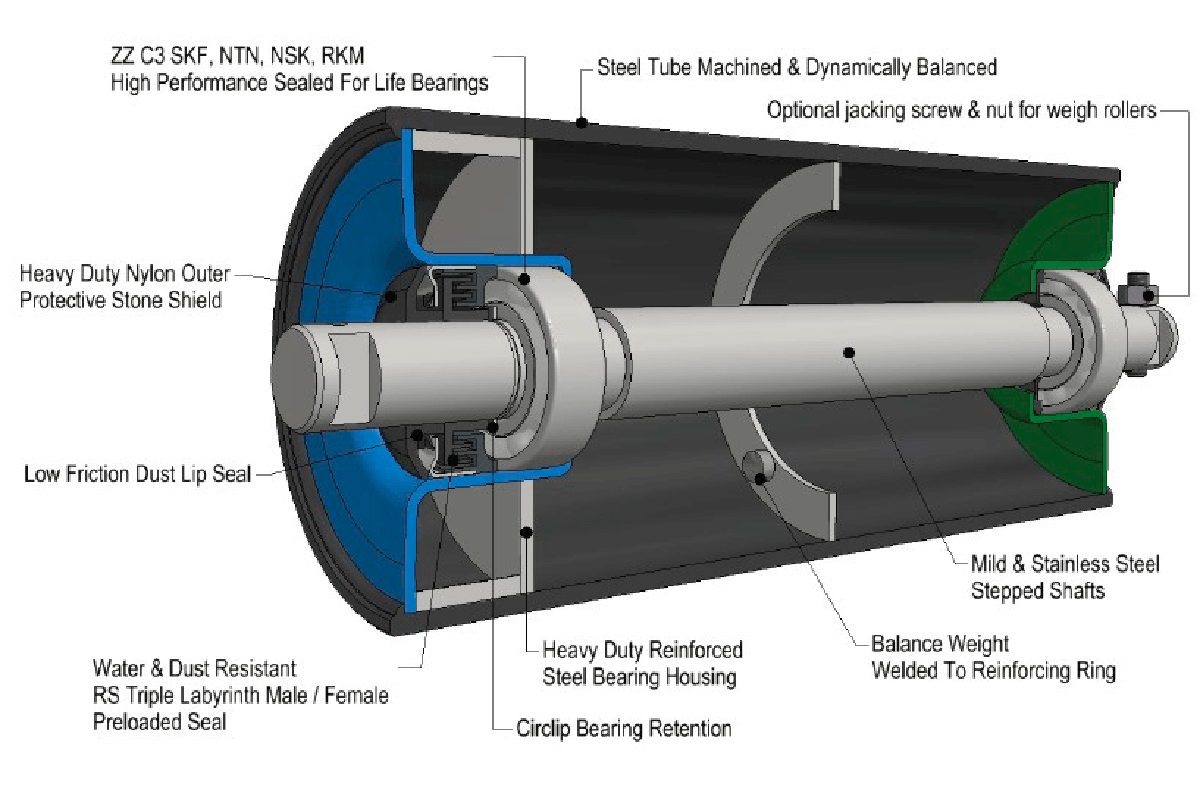

Impact Conveyor Roller Manufacturer

RKM impact rollers in general uses our RS steel roller and they are fitted with a variety of impact rings depending on the environment and impact load. These rollers are positioned on impact zones on the trough side of the conveyor.

Specification

- Rubber impact rings that comes in sections, upon which they are press fitted onto our steel rollers and locked in place using retainer rings.

- Hot bonded rubber impact rings. The steel rollers are placed in a steel mould and the impact rubbers moulded onto the steel rollers, providing a more secure bond.

- Hot bonded TPU impact rings. Similar process to hot bonded rubber impact rings, this uses high grade TPU material that provides improved oil resistance and thermal stability as compared to rubber. Other properties includes higher load bearing capability and high abrasion resistance.

Features

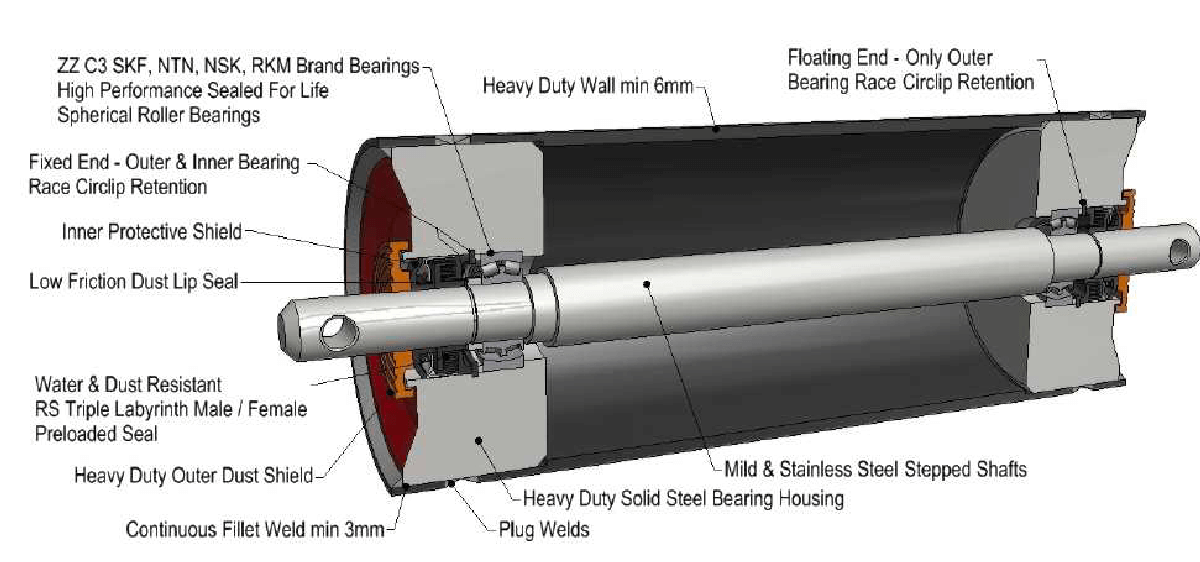

Heavy Duty Steel & Impact Rollers

RKM heavy duty steel and impact rollers are designed for heavy load capacity and high speed conveyors.

Specification

- Tube: Electric Resistance Welding (ERW) 200-350 thick walled tube.

- Impact ring: High grade TPU

- Shaft: Carbon steel S45C, DIN C45 or equivalent international standard.

- Bearing Housing: Precision machined from solid steel block. Carbon steel S45C or equivalent.

- Bearings: Spherical roller bearings

- Circlip: Heavy duty circlips.

- Seals: Labyrinth seals, rear end seals and outer protective shields made from high grade nylon. NBR lip seal for added protection against water and slurry. Added protection with outer dust shield made from nylon.

- Welding: 3mm continuous fillet weld.

Features

- Solid steel bearing housing is spot welded to tube for added strength.

- Employs “Fixed and Floating End” method, which allows the shaft to move slightly within the bearings to prevent extreme shaft deflections from ruining the bearings.

- Applied to conveyor sections that can go up to 13,000 tph capacity at 3-4m/s.

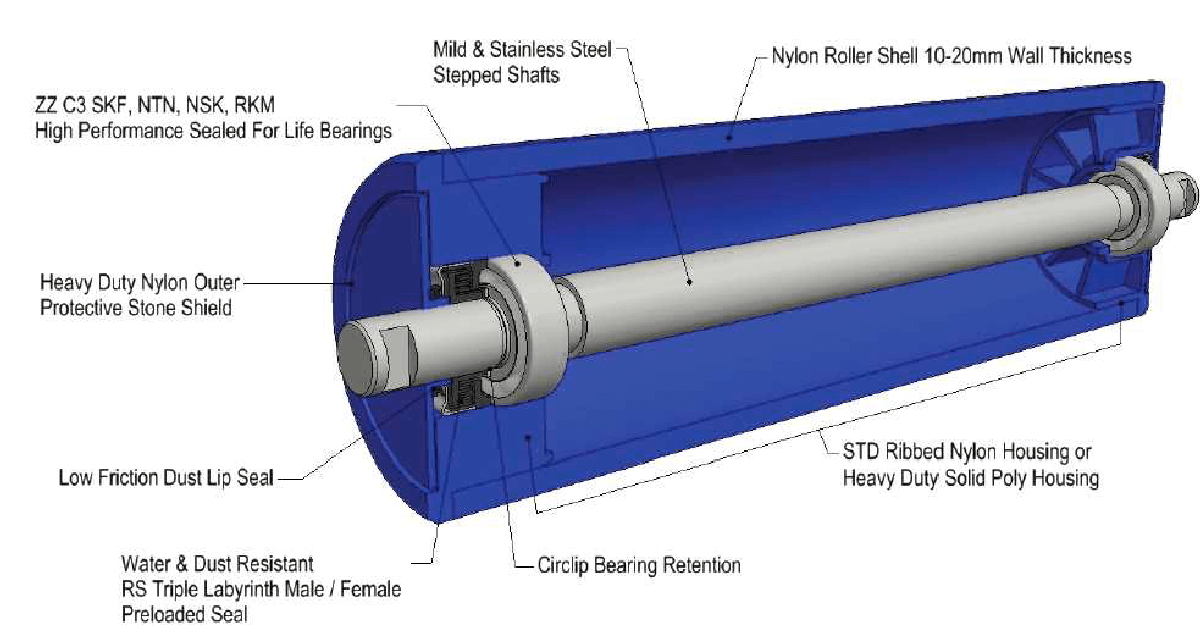

Heavy Duty Nylon Rollers

RKM heavy duty nylon roller is another anti-corrosive, lightweight and low noise option in our portfolio to further serve our customers’ needs.

Specification

- Tube: High grade nylon with excellent flexural strength, impact strength, wear and abrasion resistance.

- Shaft: Mild steel cold drawn shafts or stainless steel.

- Bearing Housing: Solid TPU housings or Nylon ribbed housings.

- Bearings: ZZ C3 Deep groove ball bearings.

- Seals: Similar to RKM RS seals package but with outer protective shield replaced with a heavy duty nylon outer protective stone shield.

Features

- Up to 50% lighter than steel rollers, which means lower power requirement for start/stop operation of conveyor and reduces potential injuries during installation and manual handling.

- Less material buildup on roller as compared to steel rollers.

- Belt friendly as damaged roller would not damage the belt.

- Anti-static and non magnetic.

- Roller tubes machined to fit meet TIR and MIS requirements.

- Roller is dynamically balance to ISOISO1940 – G16 grade or 0.014Nm, whichever is more stringent.

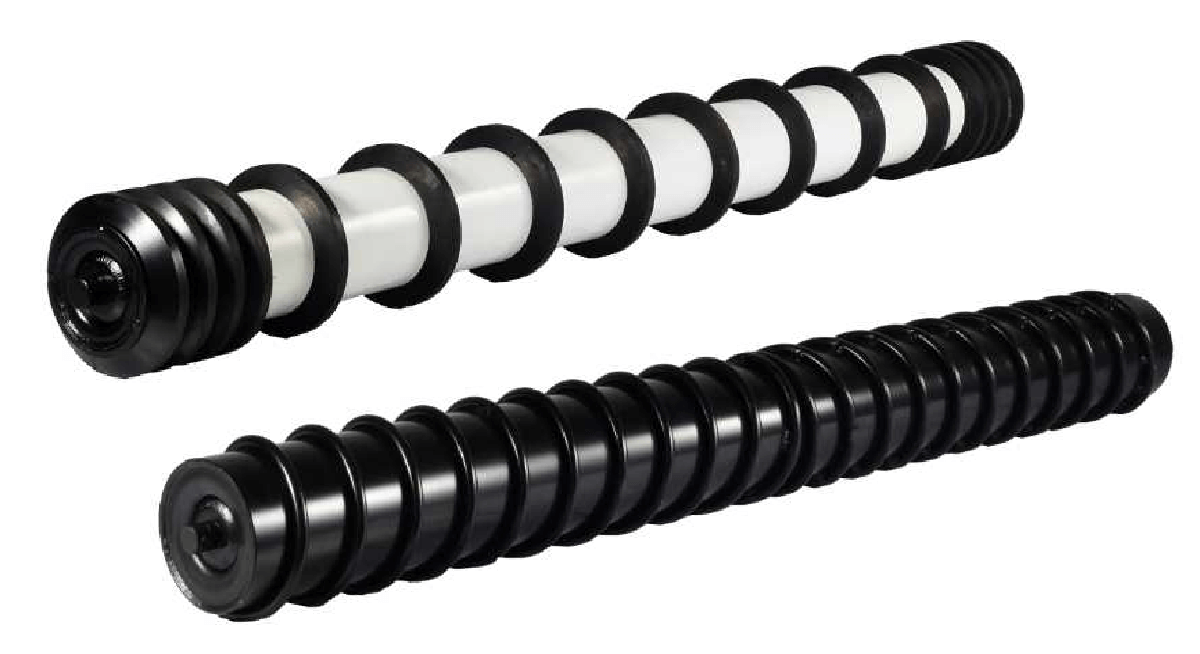

Rubber Disc & Spiral Rollers

- Rubber disc and spiral roller are used on the return side of the belt as belt cleaners.

- Spaced rubber disc on roller are made from high performance rubber. Material build-up on centre of belt will be broken up by the rubber rings.

- Spiral steel welded on the spiral roller acts as a screw and pushes the build-up material on the centre to the edge of the belt.